Zašto CAMWorks CNC softver za obradu?

CAMWorks je intuitivan CAM softver temeljen na značajkama koje pomažu povećanje produktivnosti korištenjem najboljih tehnologija u klasi i prilagodljivih alata za automatizaciju kako bi se maksimizirala učinkovitost CNC obrade.

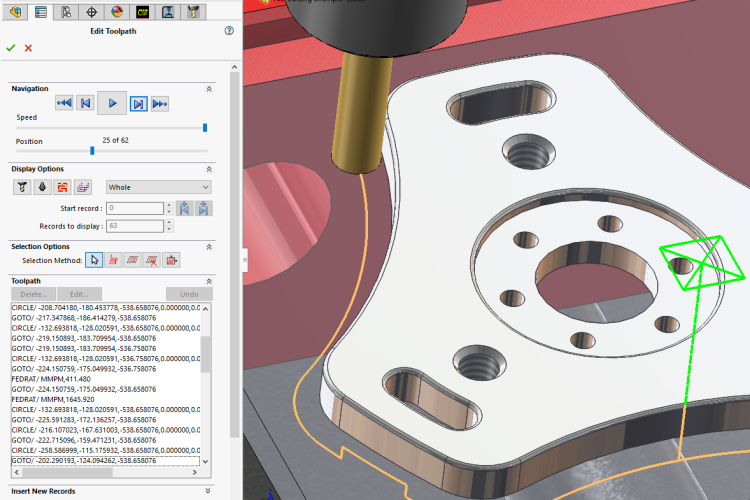

- Koristi obradu temeljenu na značajkama. Značajke obradivih dijelova prepoznaju se automatski, praktički eliminirajući ponavljajuće zadatke programiranja.

- Bilježi i pohranjuje Vaše najbolje prakse kako biste ih kasnije mogli koristiti kao bazu znanja za lakše programiranje.

- Putanje alata u CAMWorks su asocijativne i automatski se ažuriraju s promjenama u dizajnu.

Prvi i najbolji integrirani CAM softver u SOLIDWORKS

Mi smo SOLIDWORKS Gold partner za rješenja u CAM od 1998. CAMWorks je u potpunosti integriran sa SOLIDWORKS.

Kao prvo CAM rješenje koje nudi istinske mogućnosti obrade temeljene na znanju, CAMWorks prednjači u napretku u automatskom prepoznavanju značajki (AFR) i interaktivnom prepoznavanju značajki (IFR). CAMWorks nudi istinsku asocijativnu obradu – automatsko prilagođavanje promjenama modela dijela. To znači da se sve izmjene napravljene na dizajnu automatski ažuriraju u CAM podacima, što eliminira dugotrajnu preradu CAM sustava zbog izmjena dizajna.

Thanks to its seamless integration with SOLIDWORKS, CAMWorks allows you to:

- Use and manage just one file for both CAD and CAM systems.

- Use the CAMWorks machining tree and commands at the click of a button along with SOLIDWORKS, plus generate toolpaths without leaving the familiar SOLIDWORKS environment.

- Use the same SOLIDWORKS geometry to generate toolpaths to ensure the part machined is the same as the part that is modeled.

- Eliminate time-consuming file transfers using standard file formats such as IGES and STP.

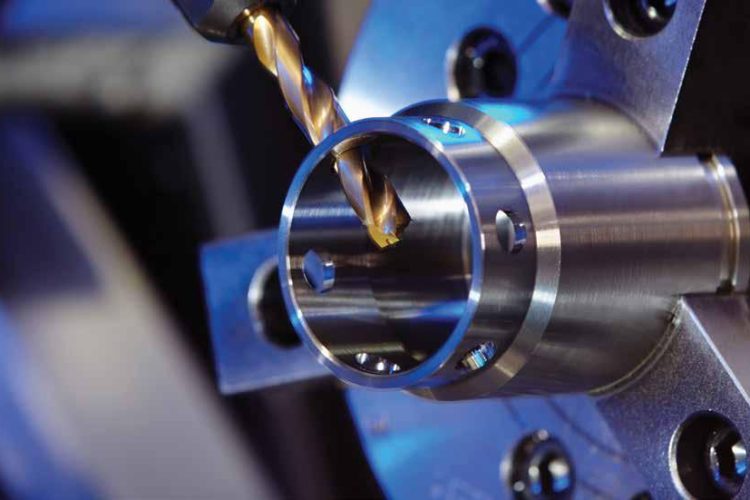

Obrada i prepoznavanje temeljeno na značajkama

Automatsko prepoznavanje značajki (AFR) automatski prepoznaje preko 20 vrsta prizmatičnih značajki na izvornim SOLIDWORKS modelima dijelova, smanjujući vrijeme programiranja za čak 90% u usporedbi s tradicionalnim CAM softverom.

With CAMWorks, you have the ability to store machining strategies based on features, which becomes a time saving practice as you can reuse the strategies to reduce programming time significantly. If a design change is needed, the integration within SOLIDWORKS allows the toolpaths to automatically update with no need to re-program.

Feature-based machining and Automatic Feature Recognition (AFR) within the software will ensure time savings when programming your CAD models. The AFR function will recognize over 20 types of machinable features in both imported and native CAD models. The option of Interactive Feature Recognition (IFR) is also available for more complex multi-surface features and will still take advantage of the machining strategies to save your machining techniques.

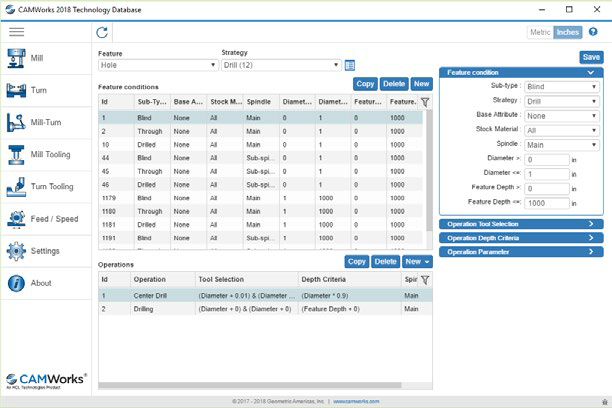

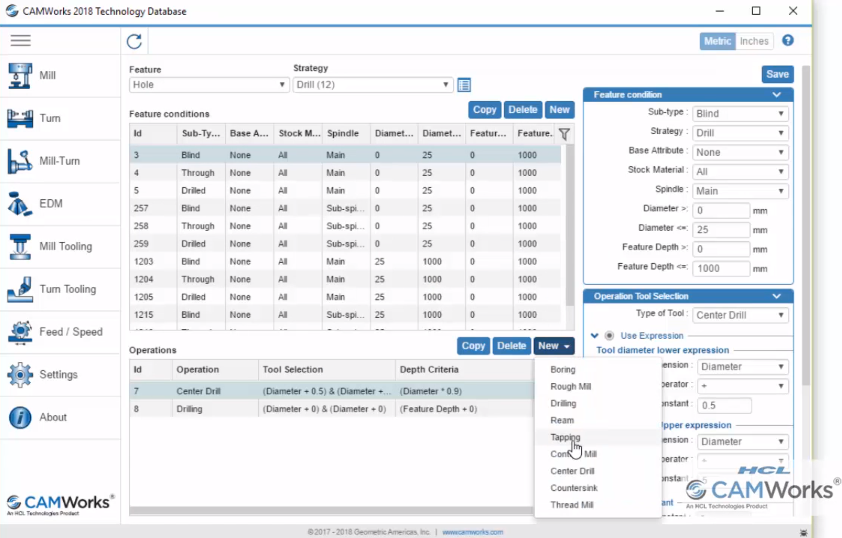

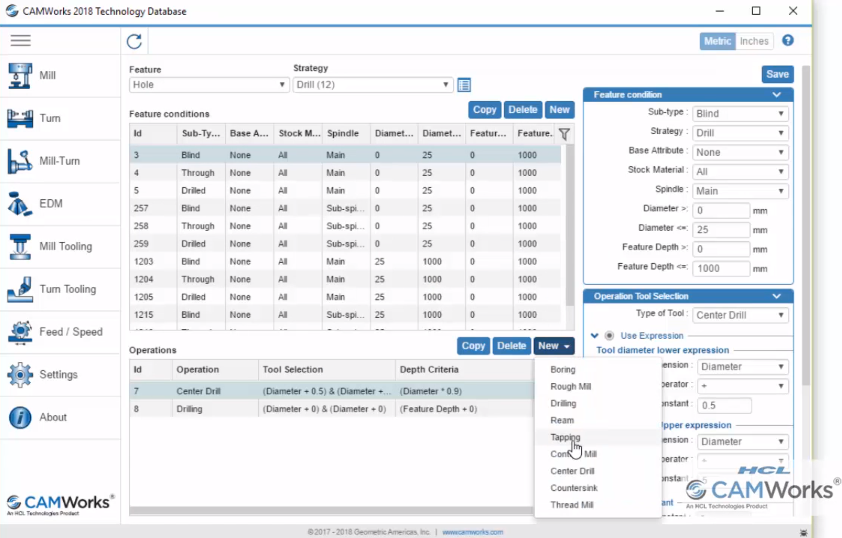

Strojna obrada temeljena na znanju

Omogućuje Vam bilježenje i ponovnu upotrebu najboljih praksi Vaših programera pomoću patentirane TechDB baze podataka, smanjujući vrijeme programiranja do 80% i pružajući bazu podataka u vlasništvu tvrtke za pohranu znanja i vještina zaposlenika.

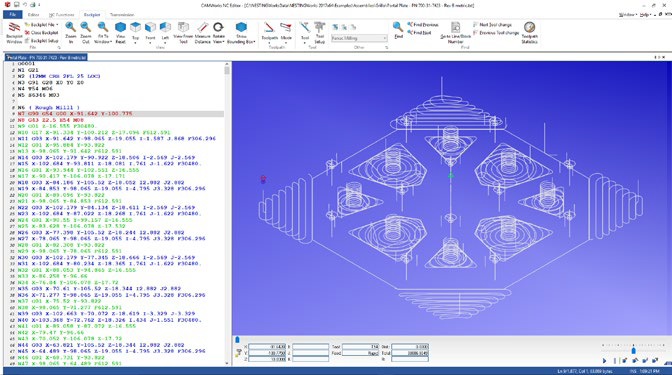

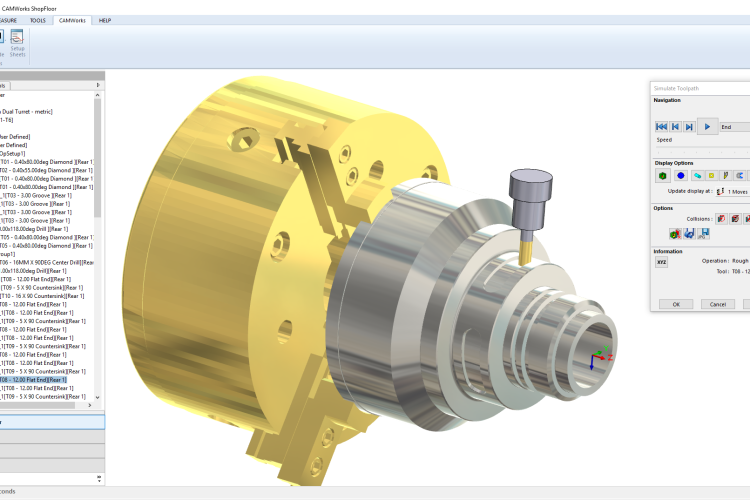

Cut Your Setup Time – CAMWorks® Virtual Machine

Performs true G-code machine simulation directly from the G-code used for the CNC machine, eliminating dry runs and set up time.

CAMWorks Virtual Machine uses the latest technology to perform true G-code machine simulation directly from the G-code used for the CNC machine. We are the first CAM software to bring true G-code machine simulation directly integrated within the CNC programming environment. Unlike other CAM systems that use cutter location (CL) data for machine simulation, CAMWorks Virtual Machine uses the actual G-code to ensure precision and accuracy.

- Cut Setup Times by 50% or more

- True G-code Machine Simulation

- Full Collision Detection – including the tool, tool holder, machine components, and fixture

- Avoid Collisions and Broken Tools

- Reduce Maintenance Costs

- Extend Machine Life

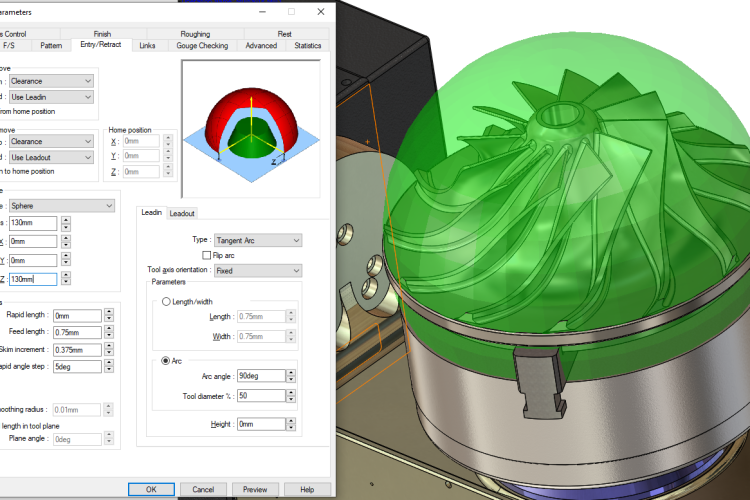

Tolerance Based Machining

Uses tolerances and features in 3D models to automatically create CNC programs.

CAMWorks je intuitivan CAM softver temeljen na značajkama koje pomažu povećanje produktivnosti korištenjem najboljih tehnologija u klasi i prilagodljivih alata za automatizaciju kako bi se maksimizirala učinkovitost CNC obrade.

The new ‘Machine to the Mean’ capabilities in CAMWorks eliminates long-standing issues surrounding differences between design practices required to tolerance parts based on fit, form and function vs. manufacturing’s need to machine geometry based on mean dimensions and tolerances.

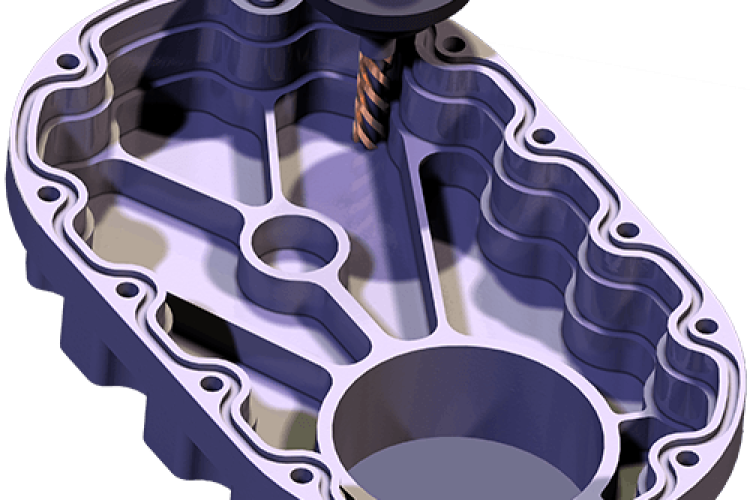

Brža vremena ciklusa – CAMWorks® VoluMill

Iznimno visokoučinkoviti mehanizam za putanju alata omogućuje Vam smanjenje vremena ciklusa za 80% za složene 3D oblike i prizmatične dijelove.

CAMWorks® VoluMill™ is ideal for complex 3-D shapes and prismatic parts as its algorithms result in more intelligent toolpaths to machine pockets, slots, and arbitrary shapes. VoluMill is well suited for machining soft as well as hard materials that are hard to chip, such as titanium, nickel-based alloys or stainless steel. The result is increased efficiency and utilization of machines, tools, labor and materials.

The high-performance roughing module, combines optimal milling paths and maximum material removal with minimized machining times. VoluMill’s unique approach to high speed material removal allows the programmer to determine the optimum material removal rate for any combination of part geometry, material, machine, and cutting tool..

- Reduce your Cycle Times up to 80%

- Reduce your programming times up to 50%

- Increase your Cutting Tool Life up to 500%

Brža vremena ciklusa – CAMWorks® VoluMill

Iznimno visokoučinkoviti mehanizam za putanju alata omogućuje Vam smanjenje vremena ciklusa za 80% za složene 3D oblike i prizmatične dijelove.

CAMWorks® VoluMill™ is ideal for complex 3-D shapes and prismatic parts as its algorithms result in more intelligent toolpaths to machine pockets, slots, and arbitrary shapes. VoluMill is well suited for machining soft as well as hard materials that are hard to chip, such as titanium, nickel-based alloys or stainless steel. The result is increased efficiency and utilization of machines, tools, labor and materials.

The high-performance roughing module, combines optimal milling paths and maximum material removal with minimized machining times. VoluMill’s unique approach to high speed material removal allows the programmer to determine the optimum material removal rate for any combination of part geometry, material, machine, and cutting tool..

- Reduce your Cycle Times up to 80%

- Reduce your programming times up to 50%

- Increase your Cutting Tool Life up to 500%

Strojna obrada temeljena na znanju

Omogućuje Vam bilježenje i ponovnu upotrebu najboljih praksi Vaših programera pomoću patentirane TechDB baze podataka, smanjujući vrijeme programiranja do 80% i pružajući bazu podataka u vlasništvu tvrtke za pohranu znanja i vještina zaposlenika.

CAMWorks FEATURES

HIGH SPEED MACHINING

Create high speed milling toolpaths with CAMWorks integrated Volumill™ toolpath. This toolpath will reduce machining time significantly and will also increase tool life.

SEAMLESS INTEGRATION

Create machinable features from imported or native SOLIDWORKS CAD models and toolpaths will update when design changes are made.

FEATURE BASED MACHINING

Reduce programming time by selecting full 3D machinable features instead of 2D chaining and profiling.

CAMWorks FOR COSTING

Check your CAM program’s estimated machining times as a cost estimation tool with the coordination of machining strategies, and Automatic Feature Recognition.

KNOWLEDGE BASED MACHINING

Leverage existing machining techniques from your companies top programmers and save these as machining strategies within CAMWorks.

TURNING WITH LIVE TOOLING CAPABILITIES

The CAMWorks Mill-Turn product includes the full turning package with milling capabilities for your multi-tasking machine centers.

AUTOMATIC FEATURE RECOGNITION

Take advantage of the Automatic Feature Recognition (AFR) tool within CAMWorks. This tool can find over 20 different machinable feature types from prismatic shapes on your CAD model.

MACHINE SIMULATION

Verify possible collisions in your CAM program using simulation options included in CAMWorks and the CAMWorks NC Editor.

CAMWorks Standard

CAMWorks Standard uključuje cijeli niz 2,5-osnog glodanja s opcijama indeksiranja 4 i 5 osi, kao i tokarenje i obradu montaže.

CAMWorks Premium

Uz značajke CAMWorks Standard, CAMWorks Premium također nudi simultane glodalice s 3, 4 i 5 osi, brzu obradu s 2,5 osi, snimanje programa s 4 i 5 osi u programu s 3 osi i CAMWorks Virtual Machine.

CAMWorks Turning Standard

Uključuje 2,5-osno glodanje Premium, 4/5-osno indeksiranje, 2,5-osno VoluMill, rotacijsko glodanje, tokarenje, glodanje-tokarenje, pomoćno vreteno i CIMCO Editor/DNC

CAMWorks Turning PRO

Za napredne tokarske aplikacije, paket CAMWorks Turning Pro uključuje opcije Mill-Turn i sinkrone obrade putanja alata.

CAMWorks Milling Standard

Uključuje 3-osno glodanje, 4/5-osno indeksiranje, 2,5-osni VoluMill, rotacijsko glodanje, tokarenje, pomoćno vreteno i CIMCO Editor/DNC

CAMWorks Milling PRO

Snažno 3-osno upravljanje putanjama alata uvedeno je unutar CAMWorks Milling Pro. Strojevi za glodanje i tokarenje također se mogu programirati unutar ovog paketa.

CAMWORKS SERVICES PROVIDED

IB-CADDY je 100% usmjeren na Vaš uspjeh s CAMWorks. Podržavamo sve vrste dizajnerskih, inženjerskih i proizvodnih timova diljem Slovenije i regiona i predani smo tome da Vam pomognemo da izvučete maksimum iz svojih CAMWorks softverskih proizvoda.

PODRŠKA ZA CAMWORKS

Vodeće usluge podrške u industriji, nude iznimnu podršku putem chata uživo i telefona, sveobuhvatne web-resurse, funkcionalnost udaljenog pristupa uživo, napredno dijeljenje datoteka, pa čak i funkcionalnost screencastinga.

CAMWORKS OBUKA

Naši CAMWorks tečajevi dostupni su u našim najsuvremenijim laboratorijima za obuku, online ili u Vašem pogonu. Nudimo sveobuhvatan raspon početnih, naprednih i specijaliziranih tečajeva dizajna.

CAMWORKS PREUZIMANJA

Primajte besplatne nadogradnje, tehničku podršku od IB-CADDY i pristup širokom rasponu resursa!