Why CAMWorks CNC machining software?

CAMWorks is an intuitive, feature-based CAM software that helps to increase productivity using best-in-class technologies and adaptable automation tools to maximize CNC machining efficiency.

- Uses feature-based machining, machinable part features are recognized automatically, virtually eliminating repetitive programming tasks

- Captures and stores your best practices so that you are able to later utilize this as a knowledge-base for easier programming

- CAMWorks tool paths are associative and update automatically to design changes

First and best integrated CAM software in SOLIDWORKS

We are SOLIDWORKS Gold-level solution partner in CAM since 1998. CAMWorks is fully integrated with SOLIDWORKS.

As the first CAM solution to offer true knowledge-based machining capabilities, CAMWorks leads the way in advancements in Automatic Feature Recognition (AFR) and Interactive Feature Recognition (IFR). CAMWorks offers true associative machining – automatically accommodating changes to the part model. This means that any modifications made to the design are automatically updated in the CAM data, which eliminates time consuming CAM system rework due to design alterations.

Thanks to its seamless integration with SOLIDWORKS, CAMWorks allows you to:

- Use and manage just one file for both CAD and CAM systems.

- Use the CAMWorks machining tree and commands at the click of a button along with SOLIDWORKS, plus generate toolpaths without leaving the familiar SOLIDWORKS environment.

- Use the same SOLIDWORKS geometry to generate toolpaths to ensure the part machined is the same as the part that is modeled.

- Eliminate time-consuming file transfers using standard file formats such as IGES and STP.

Feature Based Machining and recognition

Automatic Feature Recognition (AFR) automatically recognizes over 20 types of prismatic features on native SolidWorks part models, reducing programing time by as much as 90% compared to traditional CAM software.

With CAMWorks, you have the ability to store machining strategies based on features, which becomes a time saving practice as you can reuse the strategies to reduce programming time significantly. If a design change is needed, the integration within SOLIDWORKS allows the toolpaths to automatically update with no need to re-program.

Feature-based machining and Automatic Feature Recognition (AFR) within the software will ensure time savings when programming your CAD models. The AFR function will recognize over 20 types of machinable features in both imported and native CAD models. The option of Interactive Feature Recognition (IFR) is also available for more complex multi-surface features and will still take advantage of the machining strategies to save your machining techniques.

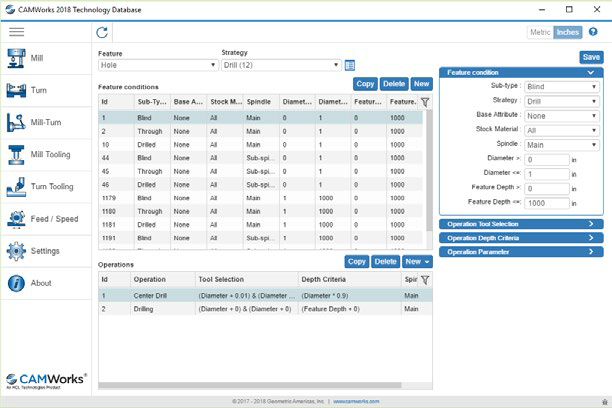

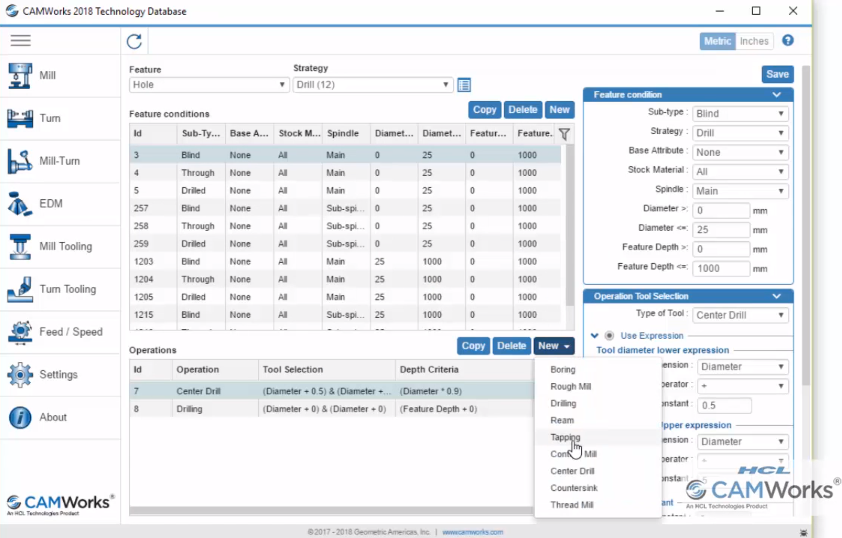

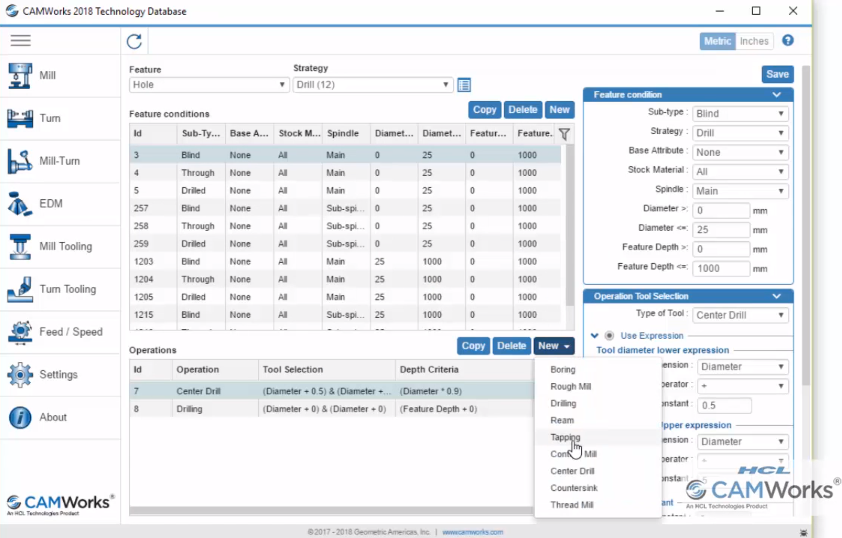

Knowledge Based Machining

Allows you to capture and reuse your programmers’ best practices using the patented TechDB, reducing programming time by as much as 80% and provides a company owned database to store employee knowledge and skill.

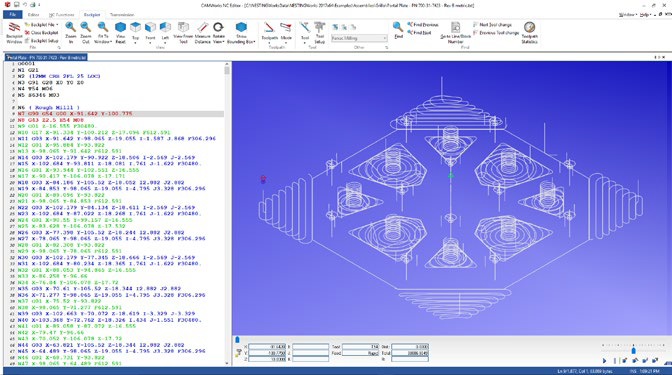

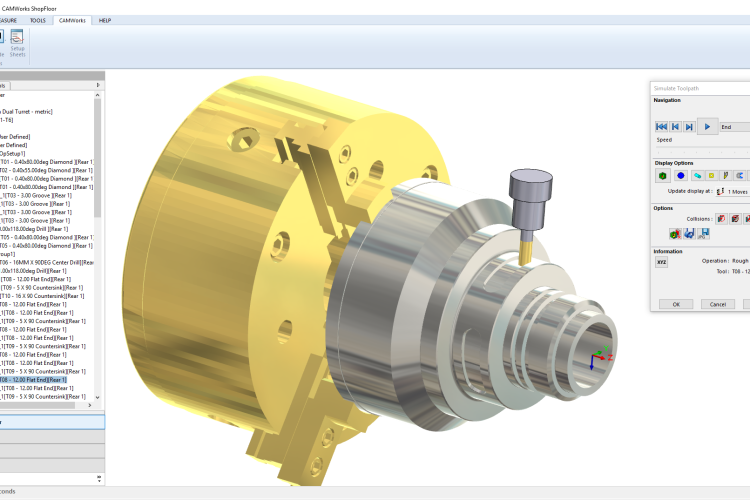

Cut Your Setup Time – CAMWorks® Virtual Machine

Performs true G-code machine simulation directly from the G-code used for the CNC machine, eliminating dry runs and set up time.

CAMWorks Virtual Machine uses the latest technology to perform true G-code machine simulation directly from the G-code used for the CNC machine. We are the first CAM software to bring true G-code machine simulation directly integrated within the CNC programming environment. Unlike other CAM systems that use cutter location (CL) data for machine simulation, CAMWorks Virtual Machine uses the actual G-code to ensure precision and accuracy.

- Cut Setup Times by 50% or more

- True G-code Machine Simulation

- Full Collision Detection – including the tool, tool holder, machine components, and fixture

- Avoid Collisions and Broken Tools

- Reduce Maintenance Costs

- Extend Machine Life

Tolerance Based Machining

Uses tolerances and features in 3D models to automatically create CNC programs.

CAMWorks is an intuitive, feature-based CAM software that helps to increase productivity using best-in-class technologies and adaptable automation tools to maximize CNC machining efficiency.

The new ‘Machine to the Mean’ capabilities in CAMWorks eliminates long-standing issues surrounding differences between design practices required to tolerance parts based on fit, form and function vs. manufacturing’s need to machine geometry based on mean dimensions and tolerances.

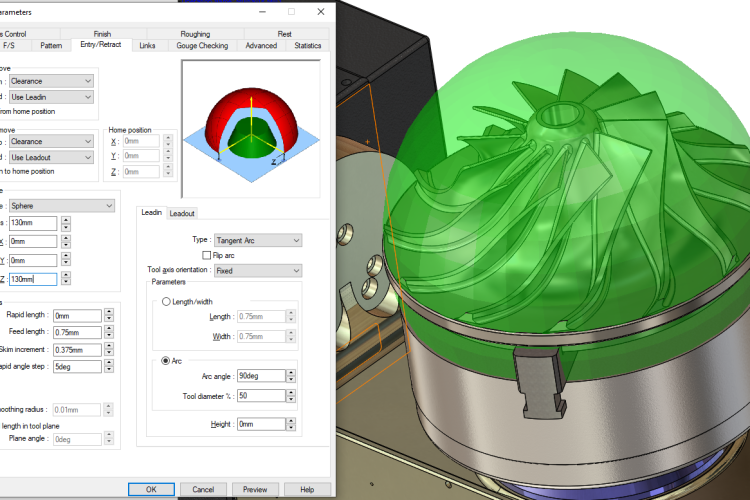

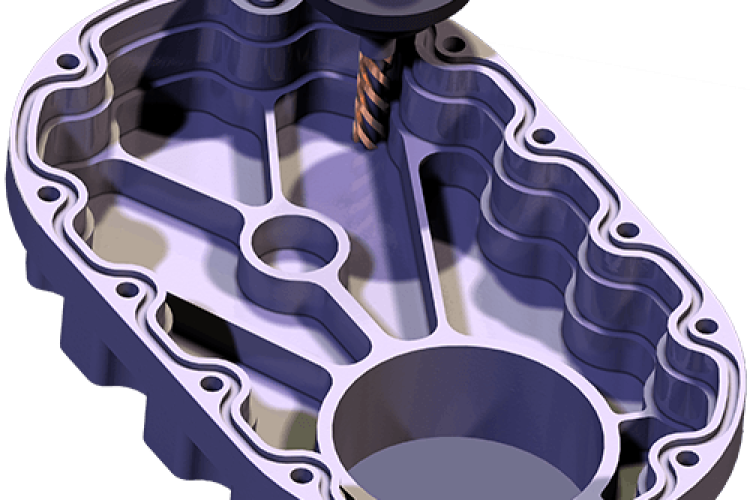

Faster Cycle Times – CAMWorks® VoluMill

The ultra high-performance tool-path engine allows you to reduce your cycle time by 80% for complex 3D- shapes and prismatic parts.

CAMWorks® VoluMill™ is ideal for complex 3-D shapes and prismatic parts as its algorithms result in more intelligent toolpaths to machine pockets, slots, and arbitrary shapes. VoluMill is well suited for machining soft as well as hard materials that are hard to chip, such as titanium, nickel-based alloys or stainless steel. The result is increased efficiency and utilization of machines, tools, labor and materials.

The high-performance roughing module, combines optimal milling paths and maximum material removal with minimized machining times. VoluMill’s unique approach to high speed material removal allows the programmer to determine the optimum material removal rate for any combination of part geometry, material, machine, and cutting tool..

- Reduce your Cycle Times up to 80%

- Reduce your programming times up to 50%

- Increase your Cutting Tool Life up to 500%

Faster Cycle Times – CAMWorks® VoluMill

The ultra high-performance tool-path engine allows you to reduce your cycle time by 80% for complex 3D- shapes and prismatic parts.

CAMWorks® VoluMill™ is ideal for complex 3-D shapes and prismatic parts as its algorithms result in more intelligent toolpaths to machine pockets, slots, and arbitrary shapes. VoluMill is well suited for machining soft as well as hard materials that are hard to chip, such as titanium, nickel-based alloys or stainless steel. The result is increased efficiency and utilization of machines, tools, labor and materials.

The high-performance roughing module, combines optimal milling paths and maximum material removal with minimized machining times. VoluMill’s unique approach to high speed material removal allows the programmer to determine the optimum material removal rate for any combination of part geometry, material, machine, and cutting tool..

- Reduce your Cycle Times up to 80%

- Reduce your programming times up to 50%

- Increase your Cutting Tool Life up to 500%

Knowledge Based Machining

Allows you to capture and reuse your programmers’ best practices using the patented TechDB, reducing programming time by as much as 80% and provides a company owned database to store employee knowledge and skill.

CAMWorks FEATURES

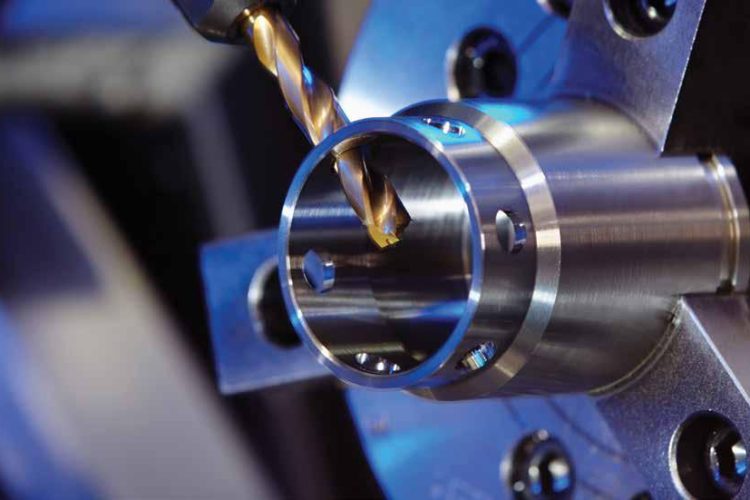

HIGH SPEED MACHINING

Create high speed milling toolpaths with CAMWorks integrated Volumill™ toolpath. This toolpath will reduce machining time significantly and will also increase tool life.

SEAMLESS INTEGRATION

Create machinable features from imported or native SOLIDWORKS CAD models and toolpaths will update when design changes are made.

FEATURE BASED MACHINING

Reduce programming time by selecting full 3D machinable features instead of 2D chaining and profiling.

CAMWorks FOR COSTING

Check your CAM program’s estimated machining times as a cost estimation tool with the coordination of machining strategies, and Automatic Feature Recognition.

KNOWLEDGE BASED MACHINING

Leverage existing machining techniques from your companies top programmers and save these as machining strategies within CAMWorks.

TURNING WITH LIVE TOOLING CAPABILITIES

The CAMWorks Mill-Turn product includes the full turning package with milling capabilities for your multi-tasking machine centers.

AUTOMATIC FEATURE RECOGNITION

Take advantage of the Automatic Feature Recognition (AFR) tool within CAMWorks. This tool can find over 20 different machinable feature types from prismatic shapes on your CAD model.

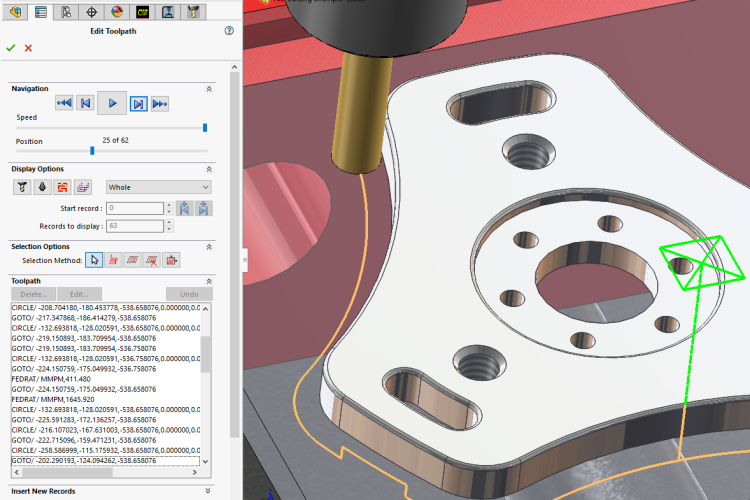

MACHINE SIMULATION

Verify possible collisions in your CAM program using simulation options included in CAMWorks and the CAMWorks NC Editor.

CAMWorks Standard

CAMWorks Standard includes a full range of 2.5 axis milling with 4 and 5 axis indexing options, as well as turning and assembly machining.

CAMWorks Premium

In addition to the features of the CAMWorks Standard, CAMWorks Premium also offers 3, 4, and 5-axis simultaneous milling machines, 2.5-axis high-speed processing, record 4 and 5-axis programs in 3-axis program and the CAMWorks Virtual Machine.

CAMWorks Turning Standard

Includes 2.5 Axis Milling Premium, 4/5 Axis Indexing, 2.5 Axis VoluMill, Rotary Milling, Turning, Mill-turn, Sub-spindle & CIMCO Editor/DNC

CAMWorks Turning PRO

For advanced turning applications the CAMWorks Turning Pro package includes Mill-Turn and synchronous machining toolpath options.

CAMWorks Milling Standard

Includes 3 Axis Milling, 4/5 Axis Indexing, 2.5 Axis VoluMill, Rotary Milling, Turning, Sub-spindle & CIMCO Editor/DNC

CAMWorks Milling PRO

Powerful 3 axis toolpathing is introduced within CAMWorks Milling Pro. Mill-Turn machines can also be programmed within this package.

CAMWORKS SERVICES PROVIDED

IB-CADDY is 100% focused on your success with CAMWorks. We support all types of design, engineering and manufacturing teams throughout the Slovenia and we are committed to help you get the most out of your CAMWorks software products.

CAMWORKS SUPPORT

Industry-leading support services, offering exceptional live chat and phone support, comprehensive web-based resources, live remote-access functionality, advanced file-sharing, and even screencasting functionality.

CAMWORKS TRAINING

Our CAMWorks courses are available in our state of the art training labs, online or onsite at your facility. We offer a comprehensive range of beginning, advanced and design specialty courses.

CAMWORKS DOWNLOADS

Receive free upgrades, technical support from IB-CADDY, and access to a wide variety of resources!